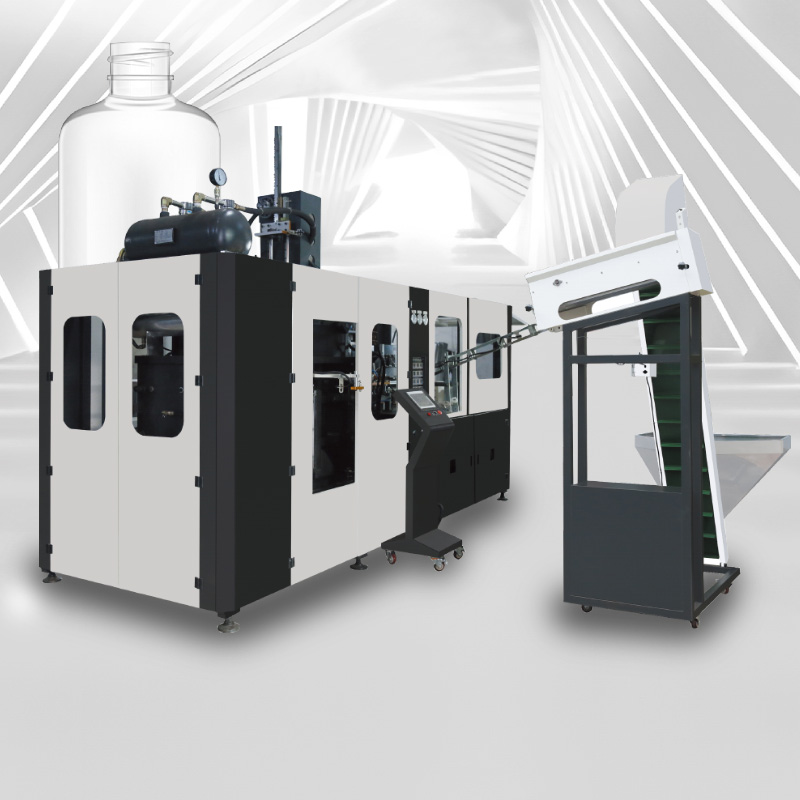

Professional manufacturer of 5L fully automatic bottle blowing machine - efficient and stable production solution

Large-Capacity Professional Design

Designed specifically for large 5L PET bottles (such as bottled water, cooking oil, and chemical containers), ensuring bottle strength and stability.

Precise capacity control (±10mL), uniform wall thickness, and resistance to pressure and deformation.

Efficient and Stable Production

Utilizes a high-torque servo drive system to meet the high-load demands of large-bottle blow molding, achieving a single-machine production capacity of 800-1500 bottles per hour (depending on bottle type).

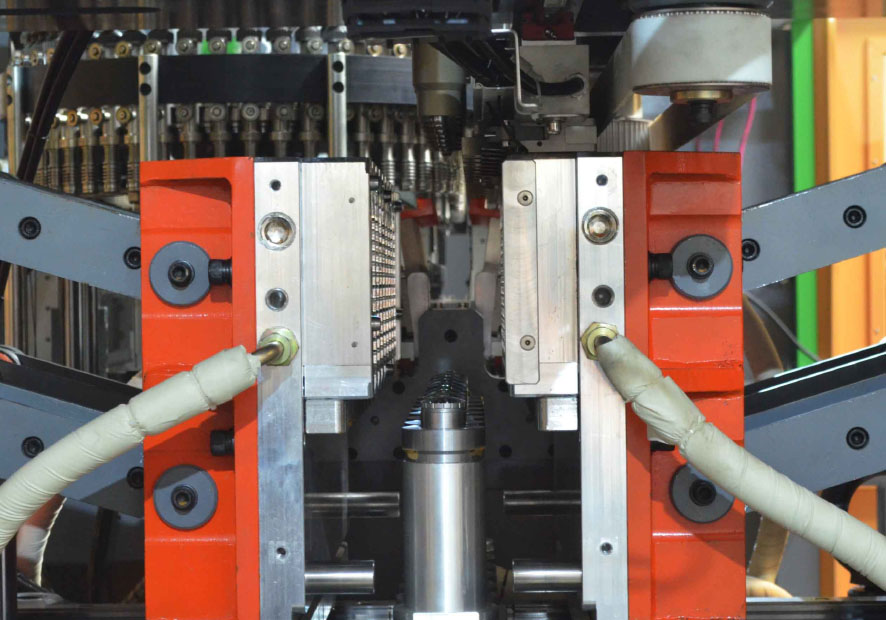

Reinforced clamping structure (clamping force 400-600T) ensures stability and durability during large bottle production.

✅ 5L bottled water (mineral water, purified water)

✅ 5L cooking oil bottle (sunflower oil, peanut oil, etc.)

✅ Chemical liquid packaging (cleaners, disinfectants, etc.)

✅ Other large-capacity liquid containers

| Project | UNIT | QA-600S-B |

| Production capacity | BPH | 600-1000 |

| Number of Cavity | 1 | |

| Clamping force | KN | 150 |

| Mould opening stroke | mm | 230 |

| Stretch stroke | mm | 350 |

| Max. Container Volume | L | 5 |

| Max. Neck Size | mm | 120 |

| Max. Bottle diameter | mm | 180 |

| Max. Bottle height | mm | 350 |

| Installed Power | Kw | 31 |

| Max. Heating Power | Kw | 30 |

| Operating Air Pressure | Kg/cm2 | 8 |

| Operating Air Consumption | liters/min | 900 |

| Blowing Air Pressure | KG/cm2 | 30 |

| Blowing Air Consumption | liters/min | 2000 |

| Cooling water Pressure | Kg/cm2 | 4-5 |

| Cooling water Temperature | °C | 10-20 |

| Cooling water Flow | liters/min | 100 |

| Measurement (L x W x H) | M | 2.5*1.5*2 |

| Machine Weight | Tons | 2 |

Four core advantages to help efficient production

High efficiency and stability, excellent production capacity

Energy saving and environmental protection, reducing operation

Stable and durable, low failure rate

Full-process service

Features

01.

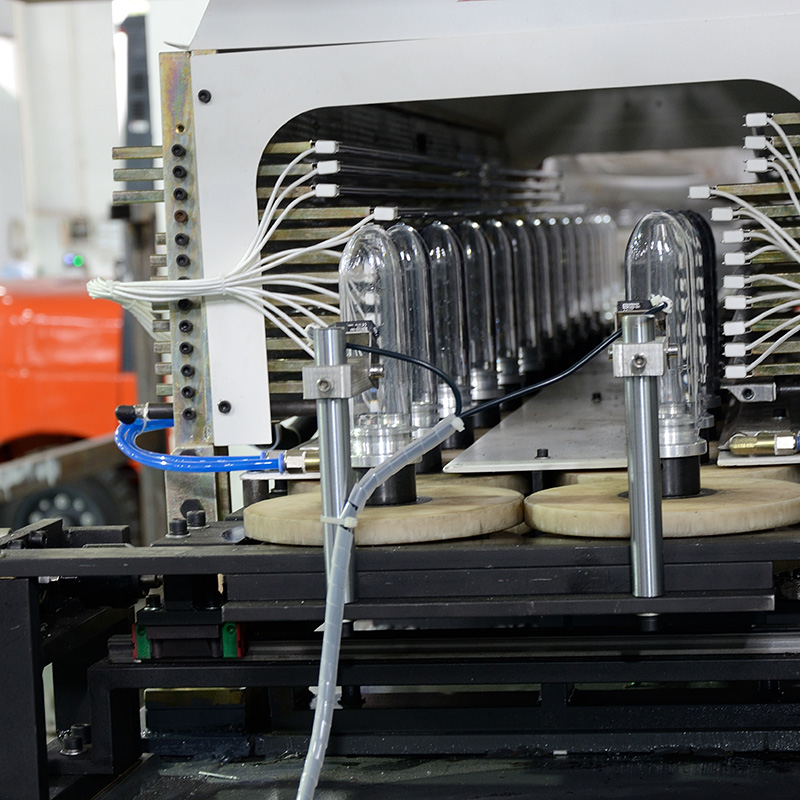

Intelligent servo drive system

02.

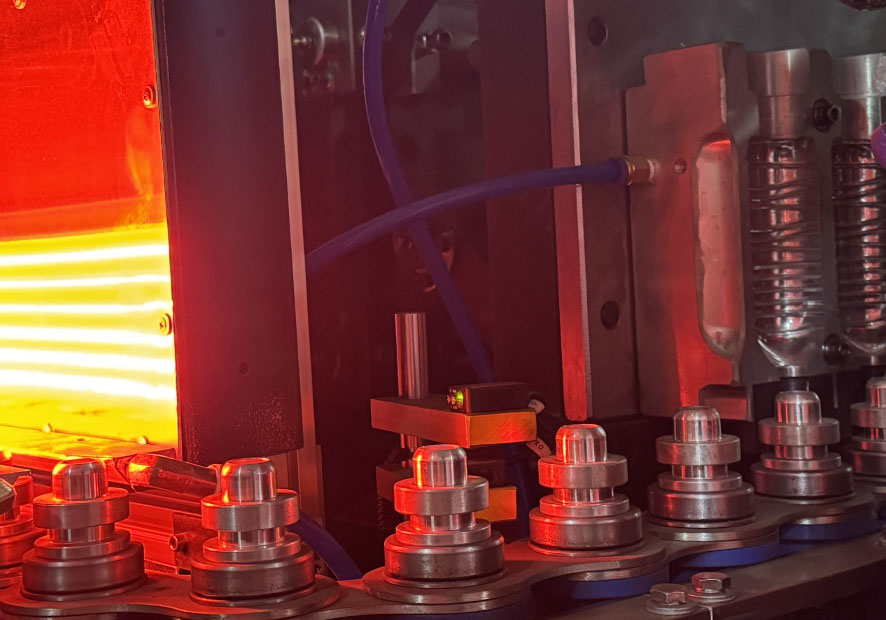

Highly efficient and energy-saving heating solutions

03.

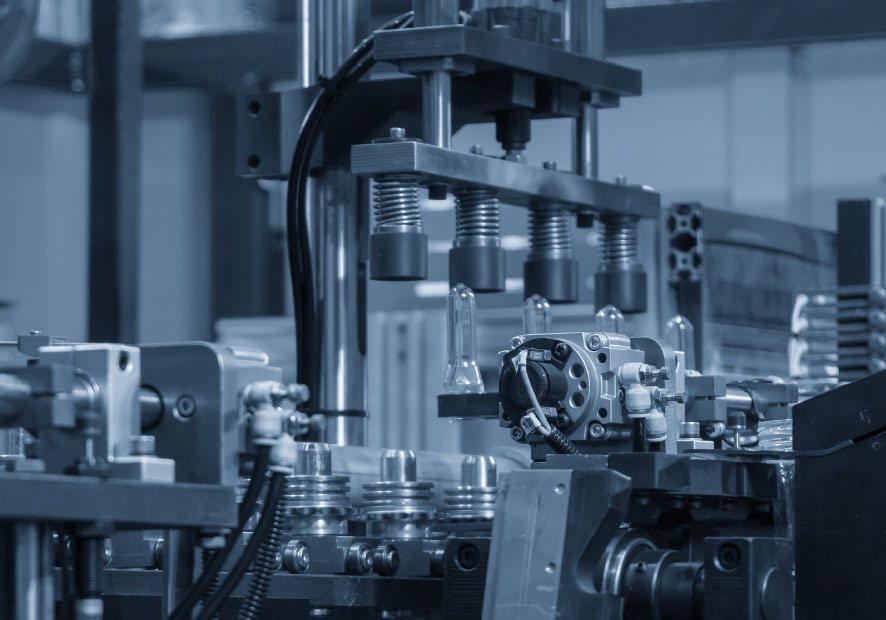

Intelligent process control systems

04.

Reliable mechanical structure

Frequently Asked Questions

Answer: It depends on the model (single or multi-cavity). Standard machines produce 1,000–5,000 bottles/hour, while high-speed models can reach 10,000+ bottles/hour. We customize solutions based on yo...

Answer: Yes! Our machines support virgin PET and rPET (up to 30–50% recycled content, depending on bottle quality requirements). We optimize heating and blowing for stable performance.

Answer: With our quick mold-change system, switching takes 15–30 minutes (vs. 1–2 hours for traditional machines), minimizing downtime.

Answer: Advanced servo-driven machines save 20–30% energy vs. hydraulic models. For example, a 20-cavity machine consumes ~25–35 kW/h.

Answer: Our machines feature:Precision temperature control (±1°C)Automatic wall thickness adjustmentReal-time defect detection (rejects faulty bottles)

Answer: Regular maintenance includes:Daily: Lubrication, air pressure checksMonthly: Mold cleaning, heater inspectionYearly: Servo motor and hydraulic system overhaul

Answer: Yes! We offer turnkey solutions, including:Preform injection machinesBlow moldersConveyors, labelers, fillersQuality inspection systems

Answer: We provide:1–2 years warranty (core parts)24/7 remote supportOn-site technician dispatch (if needed)

Ordering Process for Our Blow Molding Machines:

| Step | Stage | Description | Key Activities & Deliverables |

|---|---|---|---|

| 1 | Initial Inquiry & Consultation | You contact us to express your needs. | • Submit your requirements (bottle design, output capacity, material). • Our technical team provides initial consultation and machine recommendations. |

| 2 | Technical & Commercial Proposal | We provide a detailed offer based on your needs. | • Receive a formal quotation including machine specifications, price, and delivery terms. • Layout drawing and performance data provided for review. |

| 3 | Proposal Review & Negotiation | We discuss and refine the offer to meet your expectations. | • Clarify technical details and commercial terms (payment, warranty, training). • Adjust the proposal as needed. |

| 4 | Order Confirmation & Contract Signing | The agreement is formalized. | • Sign a sales contract or acknowledge a Proforma Invoice (PI). • Provide an official purchase order (PO) from your company. |

| 5 | Payment (Advance) | You make the initial payment to secure production. | • Pay the first installment (e.g., 30%-50% of the total amount) as per the contract. |

| 6 | Machine Production & Testing | We manufacture and rigorously test your machine. | • We build the machine to your specifications. • A factory acceptance test (FAT) is conducted. You are welcome to witness it. |

| 7 | Final Payment & Shipping Preparation | You clear the balance payment before shipment. | • Settle the remaining balance upon successful FAT and before dispatch. • We prepare all shipping and customs documentation. |

| 8 | Packaging & Shipment | Your machine is securely packed and shipped. | • The machine is crated for safe international or domestic transport. • We arrange shipment and provide tracking details. |

| 9 | Installation & Commissioning | Our engineers assist with setup at your factory. | • Our technicians arrive at your site (if included in the contract). • The machine is installed, calibrated, and tested with your materials. |

| 10 | Training & Final Acceptance | Your operators are trained on the machine. | • Comprehensive hands-on training is provided. • Perform Site Acceptance Test (SAT) and sign the final acceptance certificate. |

| 11 | After-Sales Support | Our ongoing support begins. | • Warranty period activation. • Lifetime technical support and supply of spare parts. |

Contact us

- Taizhou Pinsheng Machinery Co., Ltd.

- Niqiaojin Village, Xicheng Street, Huangyan District, Taizhou City, Zhejiang Province

- 手机: 008613058799699

- Mail: tzpinsheng@163.com